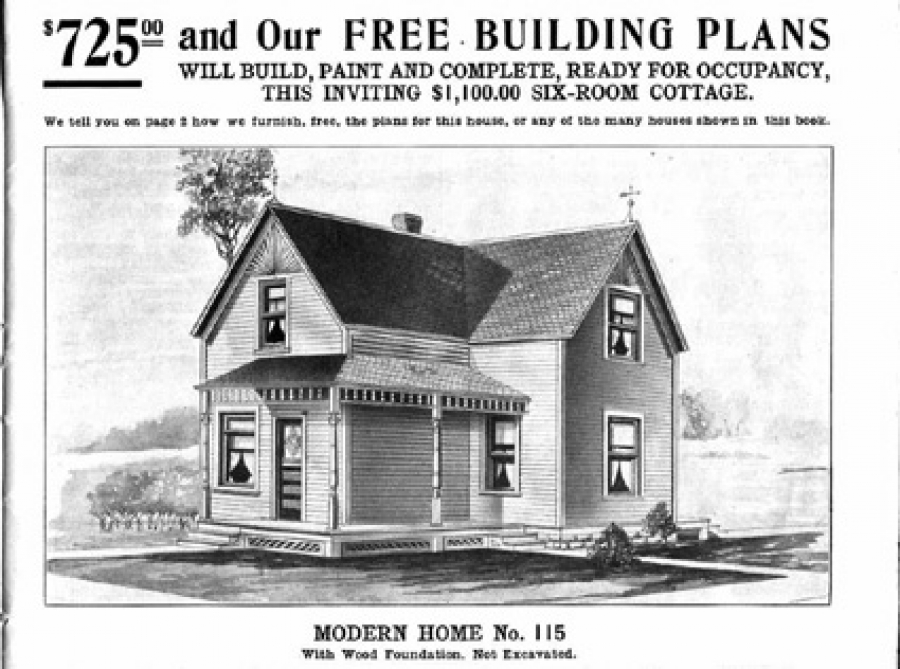

Modular home construction started gaining acceptance in the early 20th century. Sears Roebuck Co. sold between 70,000 to 100,000 pre-fabricated homes between 1908 and 1940. The market continued to grow and evolve through the remainder of the 20th century and into the 21st century.

But modular building for commercial use seems to be a market now gaining momentum.

In its latest SmartMarket Report – Prefabrication and Modularization: Increasing Productivity in the Construction Industry, McGraw-Hill Construction details the benefits available to users. Of the more than 800 architecture, engineering and contracting (AEC) professionals surveyed, 66% report improved project schedules, 65% report decreased project costs, and 77% report reduced construction site waste.

It is the last item that suggests the importance of the green benefits of modular construction:

- Less construction waste – materials that may have been assigned to one project can be re- allocated to another

- Portability – modular buildings are considered permanent structures, but if necessary, they can be disassembled, moved, and re-assembled

- Fewer site disturbances – jobsite traffic is greatly reduced, especially for vendor deliveries.

- Improved indoor air quality – the potential for high levels of moisture being trapped in the new construction is eliminated

- Reduced construction schedules – because site preparation and construction take place at the same time, most projects can be completed 30 percent to 50 percent sooner.

Sustainable Living Innovations, a consortium comprised of consultants from architectural design, construction, MEP(mechanical, electrical, and plumbing), and structural engineering, bills itself as the only “pre-fabricated system on the market that is scalable for mid-rise structures”. Their system involves pouring separate concrete floor slabs on the footprint of a building, erecting a prefabricated steel frame around it to form the structure and then using hydraulic jacks to lift into place the roof and floor slabs already fitted with walls, cabinets and fixtures.

Royal Concrete Concepts of West Palm Beach, Florida offers their modular system as a building solution that can be shipped and constructed quickly almost anywhere. A well-documented success in Haiti following the recent devastating earthquake there has RCC now setting their sights on a much bigger market. A $55-million terminal for Royal Caribbean Cruises Ltd at Labadee, 85 mi away, suffered no damage. It had been delivered by Allied Builders of Fort Lauderdale, only weeks prior, and was constructed of precast concrete panels and modular units that RCC specifically engineered to be hurricane- and seismic-resilient. Allied is now planning to use RCC for rebuilding projects in Haiti, says Alex Fullerton, Allied manager.

So what are the disadvantages of modular building?

- Limited Customization – Modular buildings can be customized to a certain extent, but these designs have limits on changes to the shape or look.

- Limited Service Area – Since the modules are constructed in a factory and then shipped to the building site, the building site needs to be within 300 miles of the factory. The costs and transportation dfficulties greatly increase for building sites farther than 300 miles.

- Confusing Zoning Rules – Since modular buildings are just now becoming popular, local zoning boards must develop a better understanding of this type of structure.

Do companies like Sustainable Living Innovations and Royal Concrete Concepts represent the future for commercial construction, or will their limitations confine them to a niche-market status?

Learn more about how mJobTime can help your company.